STEP 1

Three men assembly in 3 hours without any lifting devices or need for heavy footings

Three men assembly in 3 hours without any lifting devices or need for heavy footings

Print layout for footings with spray nozzle attachment

Move printer for escavators in just 10 minutes

Print forms for footings and flatwork

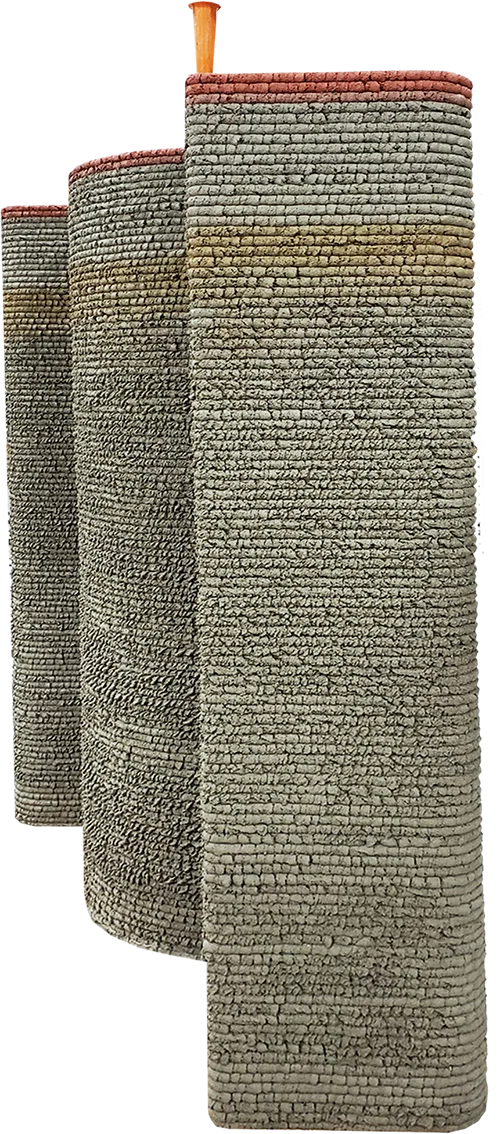

Print walls up to 10' without stopping

Add electrical boxes, rebar, and trowel walls while printing